How to choose the most suitable sewage treatment system for your factory? (Complete guide)

- release date: 2026-01-09 17:43:33

- author: Hongtai Huairui

- Reading: 330

- key words: Balancing Compliance, Cost Reduction, and Adaptability to Help Enterprises Strategically Plan Wastewater Treatment Solutions

Environmental regulations are becoming increasingly stringent year by year. By 2025, the core limit values of industrial wastewater discharge standards are expected to tighten by an average of 30%, placing growing environmental pressure on enterprises. A properly matched wastewater treatment system is not only a “passport” for compliant operation, but also a key pillar for cost control and sustainable development.

However, wastewater characteristics vary significantly across industries—from heavy-metal wastewater in the chemical industry to high-concentration organic wastewater in the food industry, and from space-constrained aging plants to newly built factories that must reserve capacity for future expansion. How can enterprises accurately select the right system and avoid risks such as “high investment but poor operation” or “insufficient system compatibility”?

This guide systematically breaks down the core logic of system selection across the entire process, providing practical, enterprise-oriented solution references.

1.Breaking Through Selection First: Identifying Your Needs Is the Core Prerequisite

Blind selection will inevitably lead to hidden risks in later stages. The first step toward accurate matching is to clearly understand your own requirements:

First, identify wastewater characteristics:

Clarify whether the wastewater comes from production processes, domestic sources, or a mixture of both. Analyze key pollutant indicators such as chemical oxygen demand (COD), five-day biochemical oxygen demand (BOD₅), and heavy metals, with particular attention to biodegradability (B/C ratio).

In the chemical and electroplating industries, the B/C ratio is often below 0.3, requiring a combination of chemical and biological treatment processes.

In the food and textile industries, the B/C ratio is typically above 0.5, where biological treatment alone can achieve efficient degradation.

It is recommended to conduct continuous water quality monitoring for 1–3 months, covering peak and off-peak production periods as well as different work shifts, to ensure the data truly reflects wastewater fluctuation patterns.

Second, calculate wastewater flow accurately:

Determine the average daily discharge, peak discharge (e.g., during production peaks or heavy rainfall), and minimum discharge. At the same time, forecast wastewater increases caused by capacity expansion over the next 3–5 years, and reserve 10%–30% of system upgrade capacity.

If the flow fluctuation coefficient exceeds 1.5, a flow equalization tank should be added or a treatment system with strong shock resistance should be selected to prevent performance failure caused by hydraulic load shocks.

Finally, define discharge and reuse objectives:

Will the treated water be directly discharged into water source protection areas, or connected to the municipal sewer network? Is water reuse required (such as for production cleaning or factory landscaping)?

Different objectives correspond to different treatment standards. For example, ultra-pure water reuse in the electronics industry requires conductivity ≤ 10 μS/cm, which necessitates advanced polishing and deep treatment processes.

2.Avoid Pitfalls in Technology Selection: Match the Process to Wastewater Characteristics

Wastewater treatment technologies mainly include physical methods, chemical methods, biological methods, and combined processes. There is no absolutely “high-end and best” technology—only the most suitable solution for specific wastewater characteristics.

Pretreatment with basic units:

Screens and grit chambers are essential pretreatment units for all types of industrial wastewater treatment systems. They effectively remove large particles and sand, ensuring stable operation of downstream equipment. For oily wastewater, dissolved air flotation (DAF) is preferred to achieve efficient oil separation.

Core treatment based on biodegradability:

For wastewater with good biodegradability, activated sludge processes (A/O, A²/O) and biofilm processes (MBBR) offer higher cost-effectiveness.

For poorly biodegradable wastewater, toxicity must first be reduced through processes such as Fenton oxidation and chemical precipitation, followed by biological treatment.

Advanced reuse relies on membrane separation:

For factories with water reuse requirements, ultrafiltration (UF) + reverse osmosis (RO) should be added after biological treatment to enable water recycling and reduce freshwater costs.

Notably, for small and medium-sized factories with limited space and insufficient operation and maintenance personnel, integrated wastewater treatment equipment has become the mainstream choice.

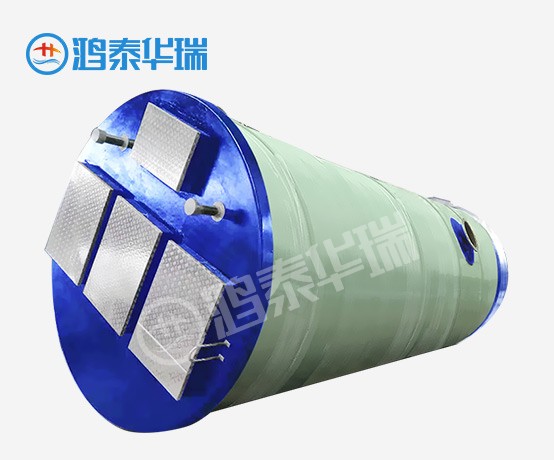

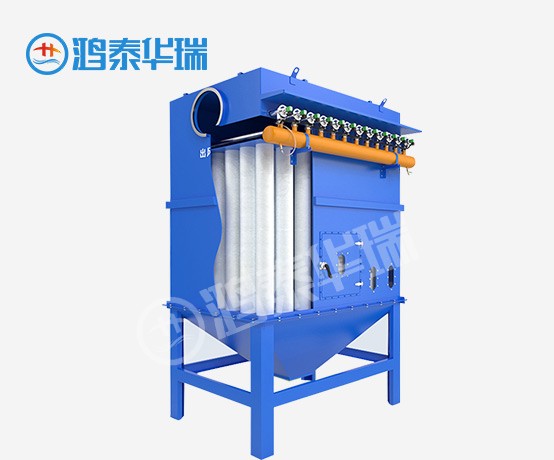

Taking Hongtai Huarui Integrated Wastewater Treatment Equipment as an example, it integrates pretreatment, biological treatment, sedimentation, and disinfection into a complete process, requiring no complex civil construction. The footprint is only one-third to one-half that of traditional decentralized systems, making it well suited for urban aging factories and small to medium-sized chemical, electronics, and food plants.

In addition, its modular design allows flexible expansion according to future increases in wastewater volume, fundamentally solving the problems of difficult retrofitting and high costs in later system upgrades.

3.Key Decision Factor: Calculate the Full Life-Cycle Cost

During system selection, enterprises should not focus solely on initial capital expenditure; long-term operational performance and costs must also be considered to avoid the vicious cycle of “high investment but poor operation.”

Initial investment cost:

The unit investment for biological treatment processes is approximately RMB 50–150 per m³ of water, while advanced treatment processes (such as ultrafiltration (UF) + reverse osmosis (RO)) typically require RMB 200–500 per m³.

Thanks to its integrated design, Hongtai Huarui Integrated Wastewater Treatment Equipment eliminates additional costs associated with separate civil works and multi-equipment integration. Taking a food processing plant with a capacity of 500 m³/day as an example, choosing this equipment can reduce initial investment by 15%–20% compared with traditional decentralized systems.

Long-term operating cost:

Electricity costs account for 40%–50% of total operating expenses, mainly for aeration, mixing, and pumping. Traditional processes such as the activated sludge method typically consume 0.5–1.0 kWh per m³ of water.

Chemical costs account for 15%–30%, with coagulants costing approximately RMB 0.5–2 per m³ and disinfectants about RMB 0.1–0.3 per m³.

Labor costs are another major expense.

Equipped with an intelligent control system, Hongtai Huarui integrated equipment can automatically adjust aeration intensity and chemical dosing, reducing energy consumption by 10%–25% compared with conventional processes. At the same time, its simplified operation allows only 1–2 operators to handle daily operation and maintenance, significantly reducing labor costs.

In addition, the equipment is manufactured with corrosion-resistant materials such as stainless steel and carbon steel, making it suitable for corrosive wastewater applications. With a low failure rate, annual maintenance costs account for only 2%–3% of the initial investment.

4.Implementation Assurance: Full-Process Control from Installation to Operation

A high-quality system requires standardized implementation and robust operation & maintenance support. Project execution should follow the full process of “preparation → design → construction → commissioning → trial operation”, with critical checkpoints including a 72-hour continuous operation test to ensure stable and compliant effluent quality.

For operation and maintenance, a daily operation log system should be established, and routine tasks such as screen cleaning and equipment maintenance should be carried out regularly.

Hongtai Huarui provides full life-cycle after-sales service, including on-site installation and commissioning, professional training for operation personnel, and 7×24-hour fault response. Warranty coverage includes 2 years for membrane modules and 1–2 years for conventional equipment, fully eliminating concerns over unorganized operations and untimely equipment fault handling.

5.Common Pitfalls to Avoid: Steer Clear of These Selection “Traps”

Blindly pursuing “high-end” processes: Wastewater with good biodegradability does not require advanced oxidation processes, avoiding unnecessary investment.

Ignoring flow fluctuations: Failing to install an equalization tank or selecting a system with weak shock resistance can lead to unstable treatment performance.

Neglecting future expansion: Sufficient system upgrade capacity should be reserved; modular equipment is preferable for small and medium-sized factories.

Focusing on investment but neglecting operation: Operational costs should be evaluated during the selection phase, prioritizing systems that are easy to operate and use readily available consumables.

The Right System = Compliance, Cost Savings & Enhanced Efficiency

The core of selecting a factory wastewater treatment system lies in balancing three key factors: treatment performance, cost-effectiveness, and adaptability. The selection process follows a full-cycle logic: needs analysis → technology screening → comprehensive evaluation → implementation.

Hongtai Huarui’s integrated wastewater treatment equipment leverages its core advantages of compact footprint, modular design, intelligence, and low cost, making it adaptable to the wastewater characteristics of various industries. From customized solution design in the early stage to operation and maintenance support in the later stage, it provides enterprises with a full-cycle solution, helping them efficiently comply with new environmental regulations while achieving both regulatory compliance and cost optimization.

Click to consult [Hongtai Huarui Environmental Experts] and get your customized wastewater treatment system solution.

Claim your free “Industry Selection Pitfall Avoidance Guide” now!

hthrjt2017@gmail.com

hthrjt2017@gmail.com