- release date: 2022-08-15 09:12:00

- author: Hongtai Huairui

- Reading: 5259

key words: Breeding farms, breeding, wastewater treatment, reclaimed water reuse

Hongtai Huarui Technology Group welcomes your visit. We have been dedicated to the environmental protection and governance industry for over a decade! We look forward to a cooperation with you!

key words: Breeding farms, breeding, wastewater treatment, reclaimed water reuse

project overview

The farm is the project base of a large-scale ecological circular agriculture demonstration science and technology park under its group enterprise. The project is planned to cover an area of 4500 acres. After completion, it will be an industrial chain project integrating feed production, modern pig breeding, modern agricultural planting, modern agricultural sightseeing, food processing and agricultural product cold chain logistics. With a total investment of 1.5 billion yuan, the project will become the largest large-scale ecological agricultural science and technology demonstration park in Yunnan Province after completion. The project is planned to be constructed in three phases. The first phase will invest 850 million yuan to build a modern breeding base with an annual output of 300,000 pigs in the Modern Agricultural Science and Technology Park, a feed processing factory with an annual output of 200,000 tons, and an annual output of 60,000 tons of organic fertilizer processing factory, a modern agricultural planting area with an annual output of 10,000 tons of vegetables and fruits, and a modern agricultural sightseeing park with an annual output of 150,000 people; the second phase will invest 300 million yuan to build a food processing industrial park to slaughter 1 million pigs a year, standardized food processing factory, large cold storage, and the third phase will invest 350 million yuan to build a large-scale agricultural product cold chain logistics industrial park, a large agricultural product trading center, e-commerce trading platform, cold chain warehouse, logistics area and supporting service facilities.

After the completion of this large-scale ecological circular agriculture demonstration science and technology park project, it will realize an agricultural circular industrial chain integrating planting, raising, adding, marketing and eating, thereby vigorously developing plateau characteristic agriculture and promoting rapid and good economic and social development.

In order to build a resource-saving and environment-friendly socialist new countryside and achieve sustainable development in rural areas, the group company plans to collect wastewater generated by breeding farms in a unified manner and build wastewater treatment stations to treat it as resources. The treated water is divided into two parts, one part is used for irrigation of dryland crops, implementing the "Farmland Irrigation Water Quality"(GB/T5084-2005) Dryland water quality standards, the other part is reused for farmland irrigation, tree watering, etc., and the reuse requirements for agriculture, forestry, and animal husbandry in the "Reclaimed Water Quality Standard"(SL368 -2006) shall be implemented; The remaining part of the effluent is discharged after meeting the "Emission Standards for Pollutants in Livestock and Poultry Breeding Industry"(GB18596-2001).

The treatment scale of this wastewater treatment and reclaimed water reuse project is 800m3/d. It adopts a combined treatment process of UASB+A2/O+SBR combined type + filtration. The wastewater reaches standard treatment and is effectively reused in the breeding base. In addition, the biogas produced by UASB is collected and utilized, realizing the recycling of resources. The project covers a total area of 900m2, the total installed capacity of the system is 121.65kW, and the operating cost is about 1.38 yuan/m3wastewater (excluding depreciation).

Design basis

(1) (Comprehensive Sewage Discharge Standard) (GB8978-196)

(2) Water used in agriculture, forestry and animal husbandry in the "Reclaimed Water Quality Standard" (SL368--2006):

(3) Dryland water in "Farmland Irrigation Water Quality" (GB/T5084-2005):

(4) Pollutant Emission Standards for Livestock and Poultry Breeding Industry (GB18596--2001)

(5) Various relevant basic information provided by the builder (water quality, water quantity, discharge and reuse standards, etc.):

(6) On-site survey data:

(7) The spirit of relevant national, provincial and regional laws, regulations and documents:

(8) Other relevant design specifications and standards.

Design principles

(1) Adopt high-efficiency, energy-saving, advanced and safe wastewater treatment technology, try to use a wastewater treatment system with simple management, low energy consumption and high efficiency, and reduce infrastructure investment and daily operating costs;

(2) In the formulation of the plan, to achieve reliable technology, economic and reasonable, combined with the specific characteristics of wastewater and the successful experience of relevant wastewater treatment at home and abroad, try to adopt new technologies on the premise of ensuring reliable functions and convenient operation and management, so as to improve the effect of wastewater treatment and reduce the cost of wastewater treatment:

(3) Adopt a combination of physical, chemical and biological treatment technologies, chemical measures to create conditions for biological treatment, with biological treatment as the main body and in-depth treatment as the guarantee:

(4) The use of electrical equipment with a high degree of automation to achieve reliable technology, economic and reasonable, to realize the automation, programming and simplification of operation management, and to achieve unmanned management as much as possible, so as to effectively reduce the operating cost of wastewater treatment;

(5) Properly treat and dispose of slag, sludge, etc. generated during wastewater treatment to avoid secondary pollution;

(6) When considering the development of the area around the wastewater treatment station, there is room for design

(7) The structures and equipment of the wastewater treatment station should be reasonably arranged, compact in structure, and save land:

(8) Design in strict accordance with the conditions defined by the construction party to meet the actual requirements of the project.

Source of pollution

According to the "Pollutant Discharge Standard for Livestock and Poultry Breeding Industry" (GB18596--2001), according to the applicable scale of intensive livestock and poultry breeding areas (in terms of the number of stocks), as well as the water quality monitoring data of large and medium-sized domestic farms, the water forecast of the project is shown in Table 1.

Table 1 Wastewater volume forecast

|

scale |

4,500 breeding pigs |

Fat 50 000 heads |

|

Water consumption standards |

The maximum allowable displacement is 150m3(104Head.d) |

The maximum allowable displacement is 120m10 headsd |

|

Water consumption scale |

67.5 m3/d |

600 m3/d |

|

Total displacement |

667.5m3/d |

|

|

Design the scale of wastewater treatment stations |

800 m3/d |

|

Processing technology

Wastewater characteristics

The main committee of wastewater in livestock and poultry farms is composed of urine, residual manure, feed residue and rinse water. The main characteristics of aquaculture wastewater are large drainage, concentration, strong hydraulic shock load, high concentration of organic matter, fast hydrolysis and acidification, and good sedimentation performance. And wastewater is often accompanied by pollutants such as disinfectant water, heavy metals, residual veterinary drugs and various zoonotic pathogens. Large-scale farms discharge a large amount of wastewater every day, and the wastewater contains a large amount of pollutants, such as organic matter, suspended matter, color, ammonia nitrogen and organophosphorus, bacteria, etc. It must therefore be properly addressed.

Process

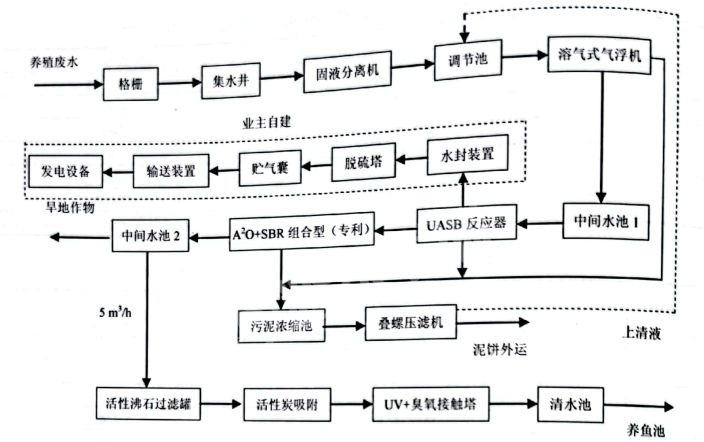

According to the water quality, quantity and treatment requirements of aquaculture wastewater in this project, it is planned to adopt "UASB+A2/O+SBR combined type + filtration", and the treated wastewater is effectively reused in the group's ecological agricultural park. In addition, biogas generated by UASB is collected and utilized, realizing resource recycling. The specific process flow is shown in Figure 2.

Process description

The aquaculture wastewater first passes through the grid to remove the large floating solids, suspended solids and insoluble substances in the wastewater to prevent blocking the pump unit, pipeline valves, etc., so as to reduce the load of the subsequent treatment structure and ensure the continuous normal operation of the subsequent treatment structure. The wastewater from the large suspended substances is removed through the grille and enters the collection well, and then lifted to the solid-liquid separator for separation by pump to remove the manure materials in the wastewater, so as to avoid these impurities from entering the subsequent treatment structure, causing the blockage of pipelines, pumps and other facilities

Fig. 2 Aquaculture wastewater treatment and reclaimed water reuse treatment process

The wastewater separated by the solid-liquid separator enters the conditioning acidification tank (the bottom of the pool is equipped with an underwater mixer), where the water quantity and quality are adjusted and the waste technology is pre-released, so as to improve the biodegradability of the bark and wood, so as to improve the treatment efficiency of the anaerobic unit. The air in the air tank is brought into the coastal gas tank by the air compressor through the jet device, and is forcibly dissolved in the water under pressure to form dissolved water and sent to the air flotation. In the case of sudden release, the air dissolved in the water precipitates to form a large number of microbubbles, which are in full contact with the suspended solids in the flocculated wastewater after the well sent from the pear is dosed, and is adsorbed in the flocculated suspended matter during the slow rise, so that its density decreases and floats to the water surface, so as to achieve the purpose of removing SS and COD.

The anaerobic reaction process in the UASB reactor is the same as other anaerobic biological treatment processes, including hydrolysis, acidification, acetic acid production and methane production. Here, different microorganisms participate in the transformation process of pollutants in wastewater and convert pollutants into final products such as biogas and water, so that pollutants such as COD and BOD in wastewater are removed in large quantities. The biogas generated by the UASB reactor passes through the water sealing device and the desulfurization tower in turn, and then enters the heart sac for storage. Finally, the electricity generated is generated by the biogas generator, which can be used to feed the wastewater treatment system

The treated effluent separated from the sludge in the UASB reactor overflows from the upper part of the overflow weir in the sedimentation area and enters the "A/0+SBR" (patented process) section of the aerobic biological treatment system. This segment is mainly composed of three parts, namely the main drinking grid and two alternating batch cells. The main gas grid maintains continuous aeration throughout the operation cycle, and during each half cycle, the two sequential batch cells alternately discharge the effluent from the SBR tank and the clarifier to the middle pool 2, and the river mud is driven into the sludge concentration tank. A part of the effluent (5m'/) of the middle pool 2 is used for irrigation of dryland crops, and the "Farmland Irrigation Water Quality" (GB/T5084-2005) dryland water quality standard is implemented.

The other part of the effluent of the middle pool 2 is lifted to the activated zeolite filter tank by lifting and aggregation, and the activated zeolite is a natural zeolite that has been activated by a variety of special processes, and the active components are artificially introduced, so that it has a new ion exchange into adsorption capacity, and its ion exchange performance is better. The adsorption performance is stronger, the adsorption capacity is also increased accordingly, which is more conducive to the removal of various pollutants in the water, its performance is close to or better than activated carbon in some aspects, its cost is far lower than that of carbon in the water, can be used for water filtration and deep treatment, not only can remove turbidity, color, odor in the water, it has an adsorption and exchange effect on the formation of heavy metal ions and organic matter in the water, and the removal rate of COD can reach more than 30%

The wastewater treated by activated zeolite filter tank is adsorbed by carbon on a topical carbon. Carbon is made from coal or wood and other materials through primary carbonization. From the dry release ratio surface area is large, so the absorption period is strong, he effective small Xie Da Zhong right organic matter (Guangbei County can be biologically distributed), only on, of rest, such as with residues from things, microorganisms and color inside, etc., can be used as an important argument for the chemical industry in the water conditions of Tongchuan, the key point of the technology is to create a kan word sex to collect the body to enrich the microbial surface in the water to form a biological structure, through the small material machine in the middle of the matter ratio protection and the adsorption of the words to go to the net to the dust, and at the same time, the biological alliance he through the degradation of the discourse sex suction rule is the enemy city is Xiaojiang, Thus, it is greatly responsible for the use cycle of the river parts.

The wastewater treated with activated carbon uses the residual pressure to enter the "UV+ ozone contact tower", where it is deodorized, decolorized, killed, disinfected and other treatments to remove the residual organic matter and inorganic matter in the wastewater, and the effluent enters the clear water pond for survival, and then reused for fish farming in the fish pond. The final effluent quality after deep treatment of the whole system meets the "Reclaimed Water Quality Standard" (SL368-2006), and the reclaimed water is used for agriculture, forestry and animal husbandry.

The remaining sludge generated by the system is stored in the sludge concentration tank, and then lifted by the sludge pump to the screw filter press for dewatering, and the dry sludge is regularly transported out for treatment.

Process characteristics

(1) Use simple physical methods to pretreat wastewater. First, a solid-liquid separator is used to separate the larger manure residue, and then the fine manure sludge is removed by the regulating tank. This pretreatment method can effectively reduce the organic matter content in wastewater without adding any flocculants, and at the same time provide good biochemical conditions for the next step of advanced and efficient anaerobic devices. The main purpose of livestock and poultry breeding wastewater treatment is to separate the wastewater from solid-liquid, and the separated solids such as manure are made into organic fertilizer through waste fermentation and other processes, and the skin water is discharged or reused after treatment.

(2) The UASB (upstream sludge bed) technology is adopted, which has the characteristics of short treatment time, high organic matter removal rate, no need for stirring and sludge return device, low energy consumption, low engineering investment, small footprint, large gas production, and easy biogas collection.

(3) The combination process of "A/O+SBR" with independent intellectual property rights is adopted, and 7 treatment units are cleverly combined, and a return device is set up, which can flexibly adjust a variety of operation modes according to the inlet and outlet water quality.

(4) Adopt coastal air flotation technology. The farm adopts the manure cleaning process of blister manure, and the concentration of suspended solids produced is very high, which cannot directly enter the biochemical reactor, and the suspended solids in the wastewater can be efficiently removed by using dissolved gas flotation.

Handling indicators

In order to more accurately understand the water quality of the wastewater generated by the farm, the wastewater was sampled and tested at the same sampling port at different times for three consecutive days, and the test results were summarized as shown in Table 2, Table 3 and Table 4.

Table 2 Wastewater test results on the first day

|

Sampling location |

project |

unit |

Analyze the results |

Minimum detection limit |

|

Pig breeding wastewater |

pH |

The dimension is one |

8.06 |

0.01 |

|

Chemical oxygen demand |

Mg/L |

6120 |

10 |

|

|

Suspended objects |

Mg/L |

7464 |

4 |

|

|

Total nitrogen |

Mg/L |

2 635.23 |

0.05 |

|

|

Total phosphorus |

Mg/L |

65.36 |

0.01 |

|

|

Nitrogen nitrogen |

Mg/L |

1 633.57 |

0.025 |

Table 3 Wastewater test results on the second day

|

Sampling location |

project |

unit |

Analyze the results |

Minimum detection limit |

|

Pig breeding wastewater |

pH |

The dimension is one |

8.48 |

0.01 |

|

Chemical oxygen demand |

Mg/L |

7280 |

10 |

|

|

Suspended objects |

Mg/L |

17436 |

4 |

|

|

Total nitrogen |

Mg/L |

2862.06 |

0.05 |

|

|

Total phosphorus |

Mg/L |

181.97 |

0.01 |

|

|

Ammonia nitrogen |

Mg/L |

1984.45 |

0.025 |

|

Table 4 Wastewater test results on the third day |

|||||

|

Sampling location |

project |

unit |

Analyze the results |

Minimum detection limit |

|

|

The raw shop also produces wastewater |

pH |

The dimension is one |

8.45 |

0.01 |

|

|

Chemical oxygen demand |

Mg/L |

5720 |

10 |

|

|

|

Suspended objects |

Mg/L |

446 |

4 |

|

|

|

Total nitrogen |

Mg/L |

1305.15 |

0.05 |

|

|

|

Total phosphorus |

Mg/L |

15.60 |

0.01 |

|

|

|

Ammonia nitrogen |

Mg/L |

804.71 |

0.025 |

|

|

Note: The above water quality monitoring data is from the grille well and the solid-liquid separator is from the water outlet

3.2.2 Design influent water quality

Through the comparison and analysis of wastewater quality test data for three consecutive days, it was found that the COD content in wastewater was lower than that of conventional similar wastewater, while ammonia nitrogen was higher, and pig urine contained copper ions, which increased the difficulty of wastewater treatment.

Based on the test results of Table 2, Table 3 and Table 4 and the water quality of the same type of wastewater, the design of this project is determined as shown in Table 5.

Table 5 Design wastewater influent water quality

|

project |

Influent water quality |

|

pH |

5~7 |

|

Suspended Solids/(mg/L) |

18 000~25 000 |

|

Chemical oxygen demand/(mg/L) |

5 000~12 000 |

|

5-day biochemical oxygen demand/(mg/L) |

1500~4 800 |

|

Ammonia Nitrogen/(mg/L) |

950 |

3.3 Design effluent quality

At the request of the construction party, the treated medium water is divided into two parts, one part is used for dryland crop irrigation, and the "Farmland Irrigation Water Quality" (GBT5084-2005) dryland water quality standard is implemented. the other part is reused for farmland irrigation, tree watering, etc., to implement the reuse requirements for agriculture, forestry and animal husbandry in the "Reclaimed Water Quality Standard" (SL368-2006); The remaining part of the effluent is discharged after reaching the "Pollutant Discharge Standard for Livestock and Poultry Breeding" (GB18596-2001). The specific effluent water quality is shown in Table 6, Table 7 and Table 8.

Table 6 "Pollutant Emission Standards for Livestock and Poultry Breeding" (GB18596-2001)

|

serial number |

project |

Troubleshooting standards |

|

1 |

pH |

6~9 |

|

2 |

Ammonia Nitrogen/(mg/L) |

≤80 |

|

3 |

CODcr/(mg/L) |

≤400 |

|

4 |

BOD5/(mg/L) |

≤150 |

|

5 |

Suspended Solids/(mg/L) |

≤200 |

|

6 |

Fecal coliform bacteria/(pcs/L) |

≤10 000 |

|

7 |

Number of worm eggs/(pcs/L) |

≤2 |

Table 7 "Reclaimed Water Quality Standards" (SL368-2006) is used for agriculture, forestry and animal husbandry

|

serial number |

project |

Emission standards |

|

1 |

pH |

≤5.5~8.5 |

|

2 |

Chromaticity/degree |

≤30 |

|

3 |

CODcr/(mg/L) |

≤40 |

|

4 |

BOD5/(mg/L) |

≤10 |

|

5 |

Suspended Solids/(mg/L) |

≤30 |

|

6 |

Fecal coliform bacteria/(pcs/L) |

≤2000 |

|

7 |

Number of worm eggs/(pcs/L) |

≤2 |

Table 8 "Farmland Irrigation Water Quality Standards" (GB/T5004-2005) Dryland Water Quality Standards

|

serial number |

project |

Troubleshooting standards |

|

|

1 |

pH |

≤5.5~8.5 |

|

|

2 |

Anionic surfactant/(mg/L) |

≤8 |

|

|

3 |

CODcr/(mg/L) |

≤200 |

|

|

4 |

BOD5/(mg/L) |

≤100 |

|

|

5 |

Suspended Solids/(mg/L) |

≤100 |

|

|

6 |

Fecal coliform bacteria/(pcs/L) |

≤100 |

|

|

7 |

Number of worm eggs/(pcs/L) |

≤2 |

|

Previous Article:Circulating cooling water treatment proj...

Next Article:Process design case of organic waste gas...

The content you might be interested in

Environmental Protection Information

Recommended Products